5 ERP Benefits for Batch Process Manufacturing

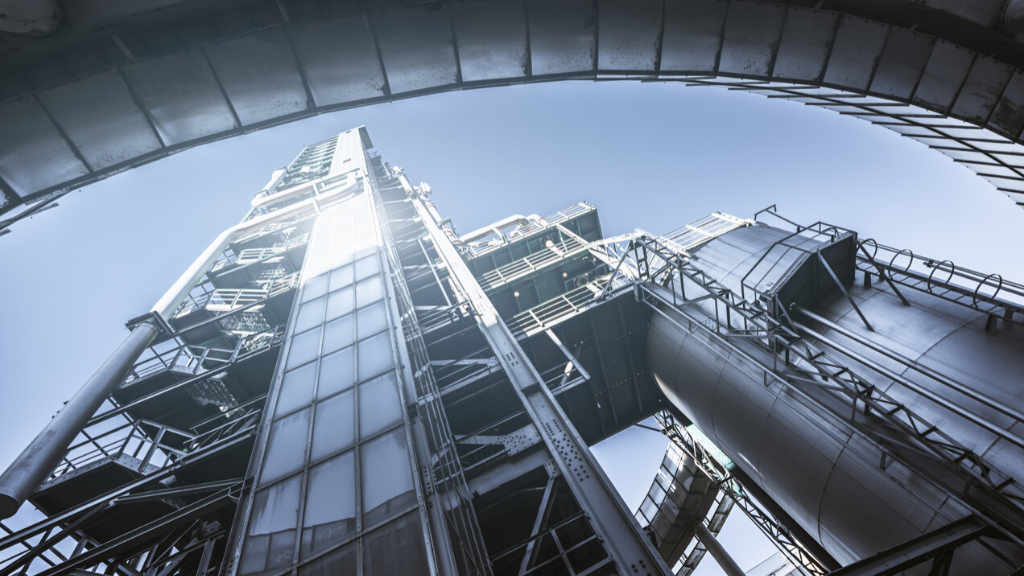

Batch process manufacturing is an approach to creating products that use recipes or formulas. Process manufacturers bring together the various components of a product through step by step progressions. Unlike discreet manufacturing, in which the final product can often be disassembled to some degree, the raw ingredients contained in an item after batch processing typically can’t be detached or removed from the final product.

Food and chemical companies are two prime examples of industries that utilize batch processing. For instance, producing baked goods, soft drinks, refined oil, and paints would be considered process manufacturing. Batch manufacturers must have a way of ensuring the integrity of their products since low quality can put health and safety at risk.

Process manufacturers require a software solution that centralizes their daily processes into a database that can coordinate the strategic elements related to the shop floor, inventory, finances, customer relationships, and distribution management. Synchronizing these critical functions can streamline their operations, boost productivity, and increase revenue.

Enterprise resource planning (ERP) solutions can meet the specific needs of batch process manufacturers. Manufacturing ERP software is tailored specifically for the manufacturing environment. It understands the challenges of batch manufacturing and provides solutions that allow batch process manufacturers to run their businesses more efficiently and profitably.

Here are five of the main benefits of ERP.

Quality inspection and reporting

Food and beverage manufacturers are constantly reminded of increased consumer scrutiny, governmental regulations, and product recalls. These companies must have efficient and effective procedures to ensure the quality of their products. ERP systems can track, trace, and monitor manufacturing from a quality perspective, and they can provide quality management tools.

Batch process manufacturers often require corrective action to be quick and effective, so sophisticated query capabilities are necessary for practical data analysis. Along with real-time reporting, this enables the identification of root causes that threaten quality.

Lot tracking and traceability

Lot tracking from raw material to finished goods is essential for process manufacturers. That capability becomes critical in a recall when there is tremendous pressure to complete a successful recall as quickly as possible. Businesses need information fast, and that is something they can get from a high-quality ERP system.

Full traceability allows for the retrograde analysis of batches that come under question. Since ERP software tracks and records all batch transactions, the company can trace any specific supply of materials to a particular manufacturing batch.

Production management

The production management module of ERP helps companies manage the shop floor. If applicable, it can be integrated with computer-aided design (CAD) and product lifecycle management (PLM) solutions to provide real-time data concerning the product lifecycle.

Production management also shows how labor and time are being allocated, helping to improve efficiency and consistency. Other vital functions include cost estimation, creating competitive quotes, capacity planning, and scheduling.

Supply chain management

The features of supply chain management can help organizations decide which suppliers are the best value for the company. The tool can also assist with forecasting demand, automating the quote process, managing raw material bids, and might even provide support for requests for proposals (RFP). Other features include a program where manufacturers can access inventory details such as requests for quotation (RFQ) and purchase orders (PO).

Batch and recipe management

Batch and recipe management software can help process manufacturers confirm that their batches are:

- Automated and adjusted per recipe

- Achieved at peak efficiency

- Assigned to the appropriate equipment

- Based on set and precise parameters

The software interacts with the plant’s control systems and interrelates with operators to guide batch activity. It can also standardize various processes across the enterprise. The software records activities to a historical database for documentation.

The ERP experts at Decision Resources are on standby to provide the information you need to streamline functions, improve productivity, and introduce and maintain an integrated and more efficient way of doing business within your food and beverage manufacturing environment. If you’re ready to take a step toward transforming your business with an ERP, please get in touch through our online contact form, call 412-562-9660, or email us at info@decision.com.

Similar Blogs

Decision Resources Featured on Crunchbase

Chips, drugs, and steel — how to prepare for Trump tariffs