How an ERP System Helps with Supply Chain Management

As the saying goes, you’re only as strong as your weakest link. In manufacturing, the supply chain is one of the most critical links there is, but it’s becoming increasingly difficult to manage. Customers expect quick responses and deliveries, while suppliers are globalizing every day, adding new challenges to accessing the materials you need. As a manufacturer, you might feel stuck in the middle, trying to make and keep everyone happy. ERP supply chain management is an excellent solution to this problem.

With ERP supply chain management functionality, your business accesses greater insights into every part of the supply chain. No longer a potential weak link to bring the company down, the supply chain can become a substantial factor in your success. ERP supply chain management optimizes every process, making it faster, more productive, and better integrated with every other part of your business.

Better Planning

ERP supply chain management puts planning in your control, based on real, accurate data. Instead of guessing at what inventory you need, what raw materials are required to create that inventory, and how you are going to move it to customers in what quantities, you can use the ERP. A sound ERP supply chain management system forecasts every part of your manufacturing processes from start to finish so you can keep it all balanced.

Improved Efficiency

There are many different departments, organizations, and individuals making up your supply chain. If one of those links happens to slow down for any reason, the entire chain loses efficiency. With ERP supply chain management, you have insight into everyone and everything that can either speed you up or slow you down, and you’re making business decisions based on that information. There’s no more lost time to manual data entry or inaccurate predictions.

More Flexible Supply Chain Solutions

ERP supply chain management lets you be flexible and agile as your business, your suppliers, your customers, and even the entire industry shift. ERPs are known to be future-proof, customizable, and modular as technology changes, and your organizational processes evolve. The next time something new or different pops up in the supply chain, don’t panic — your ERP can help your business adapt.

Enhanced Procurement

ERP supply chain management keeps a careful eye on everything that can influence your supply chain negatively or positively. These systems track factors like vendor and supplier availability, the volume of customer orders, and transportation, so you can procure the materials you need to meet an accurate promise date.

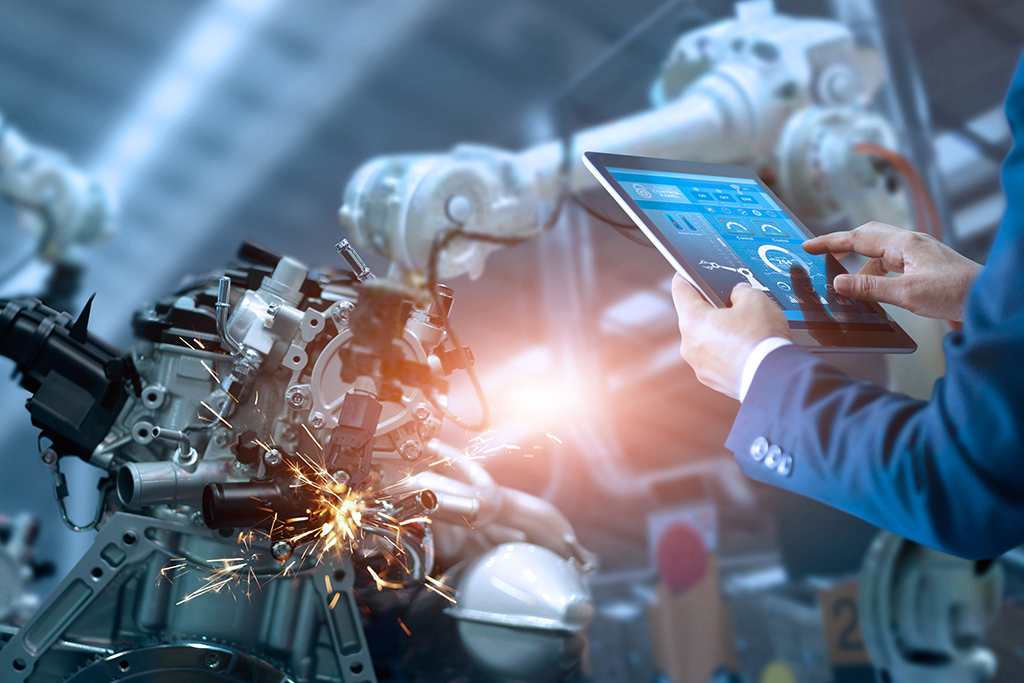

Streamline Manufacturing Operations

Labor, machines, and processes are all part of the ERP supply chain management system, ensuring that you have the right people, tools, and processes online for each job. The system knows what you have procured, what you need to make, and when it needs to be done, creating a smooth, predictable production system complete with quality control.

Delivery and Logistics

Delivery and logistics comprise the last but one of the most critical stages of supply chain management. ERP supply chain management continues to work hard for you here, handling everything from automated invoicing to a customer portal to track the delivery. Even packaging details can be handled by the ERP to meet the parameters you have set out.

Decision Resources is here to answer any questions you may have about ERP supply chain management. Our friendly ERP experts are always standing by. Call us at 412-562-9660 or email info@decision.com to learn more.

Similar Blogs

Decision Resources Featured on Crunchbase

Chips, drugs, and steel — how to prepare for Trump tariffs