Planned Order Consolidation

Reducing variability in the Procurement Cycle

Machine Tools at Cross Manufacturing

In the last twenty years I have assisted an average of three to five supply chain teams with their MRP, MRP II and now ERP implementations every year. We have grouped components by commodity, defined buyer and planner schemes to add useable dimensions to the huge list of raw materials/purchased components, and we have weathered the storms of the shifting attitudes toward suppliers and our mutual relationships. It’s all been good.

The one thing that seemed to remain consistent throughout this period was the surprising lack of a purchasing policies when it came to Planned Order Consolidation. Purchasing is a process; and reducing variability in the process will improve the quality of the output. However, I frequently get a quizzical look when I ask about a purchasing policy. Generally, the response is related to limits of dollar authority. When I asked a friend of mine who was working for a client at the time for his comments, he simply smiled and said, “We buy a bunch on a hunch.” I knew he was kidding, but I also knew he and his organization had not thought through the importance of managing both the frequency and timing of the procurement activity, and in doing so, stopped short of realizing one very powerful way of eliminating waste in the supply chain. Here’s the thing; price point and vendor imposed minimums/multiples seem to be where the typical analysis stops. I’m not saying these don’t matter – and I’m certainly not saying these don’t exist – I’m saying that we need to move on from these very real, but limited, considerations and look toward a process definition in the procurement arena no differently than we would look at process definitions and controls in the manufacturing cells.

ABC Analysis

Before we define the planned order consolidation rules, I want to look at the typical ABC analysis tools we have at our disposal. In the Infor CloudSuite ERP solution we have a variety of methods to define ABC code, and I want to focus on one of them. Year-to-date usage value describes an analysis based on the year-to date usage of each purchased item weighted by the unit cost of the item. Standard costing or actual costing is not an issue – it’s the product of the usage and the cost that give us the basis for the consolidation.

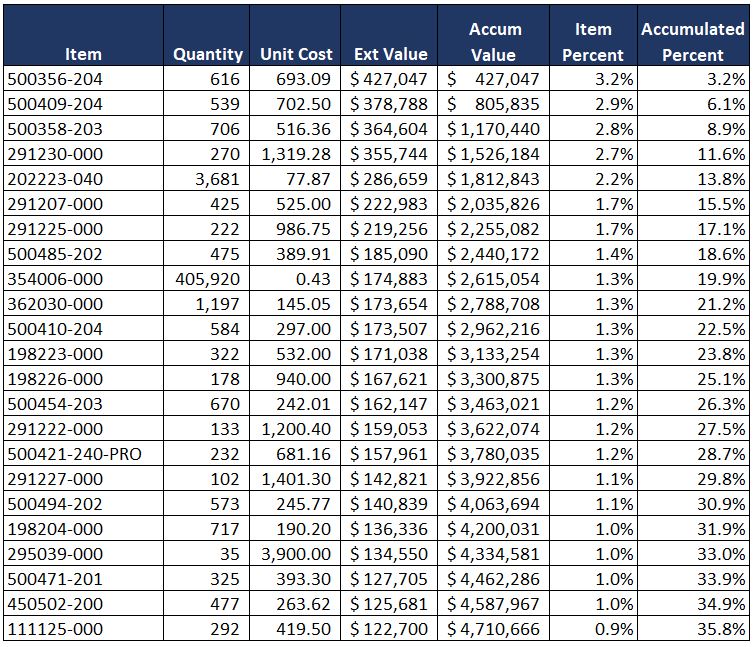

Consider the table below:

In the top 35% of this sample data set I have components ranging in usage from 35 to over 400,000 and ranging in cost from $0.43 to $3,900.

In the top 35% of this sample data set I have components ranging in usage from 35 to over 400,000 and ranging in cost from $0.43 to $3,900.

To properly assess the “ABC” value of a component, ICSI includes both the usage and the cost. Be careful not to mix manufactured components or assemblies with the analysis of purchased items. They need to be done separately to prevent the manufactured items from overwhelming the analysis.

Items with Usage

Another observation I can make about this data is that for the typical manufacturer in my client base, there is a much steeper pareto of this data than the generally accepted 80/20 rule. In the first place, the bottom half (or more) of the analysis is comprised of items with no usage. This is not limited to my Oil & Gas clients, it’s not limited to my electronics equipment and accessory manufacturers, it’s not limited to my Make-to-Order or Make-to-Stock companies – It is all of them.

ABC Classification of inventory items is not a new subject. Perhaps leveraging the ABC analysis to control planned order consolidation is. I never have any trouble building consensus for the general rule that we play our A items a little closer to the vest than our Cs; everybody knows that. But can we leverage the ABC logic to create a specific policy within which the procurement teams can operate? The answer is yes.

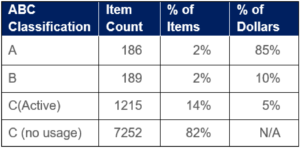

Using the customer’s data in the previous section, we created this table of data for all purchased components in the system; weighting the annual usage by the unit cost and sorting the table in descending order by extended value. We then defined an arbitrary cut-off which states that the top 85% would be classified as “A” items, then next 10% as “B”s and the bottom 5% as “C”s.

Using the customer’s data in the previous section, we created this table of data for all purchased components in the system; weighting the annual usage by the unit cost and sorting the table in descending order by extended value. We then defined an arbitrary cut-off which states that the top 85% would be classified as “A” items, then next 10% as “B”s and the bottom 5% as “C”s.

Finally, we isolated the “C” items that had no usage – showing the results in this table. Notice the distribution – 2% of their items represent 85% of their purchasing dollar. Will you get these same results? Probably not, but one thing I have seen over and over again is that the distribution is much different than expected. Do the analysis. Your results will be different, but not so different that this principle does not apply. So, how do we use the ABC analysis to create a policy for consolidating Planned Orders?

Planned Order Consolidation

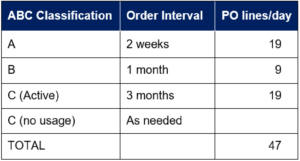

With the purchased components and raw materials properly aligned based on their relative value to your cost of goods sold, you can now define an order policy or cadence for the procurement activity. Here’s the question: How often (and therefore how many) of an item should you buy? What is the order policy at your organization? How frequently do you buy an item? When I ask these questions the most common answers I hear are: “Some of our items have vendor imposed minimum,” or “We like to keep 3 month’s supply of this item,” or “Our Purchasing approval process is based on the dollar value of the purchase order.” What about your company? At this point I go back to the comment I made earlier, Isn’t it true that you play your “A” items a little more close to the vest than your “C”s? And now it starts to jell. My starting point for a purchasing policy will be something like the plan shown in the following table. Can the organization support 65 purchase order lines per day? That is going to be a function of the complexity of the process, as well as the number of buyers and the distribution of these items across the purchasing organization. If I sense a large push back at this point, I usually half the frequency of the “A”s. If you order “A”s every two weeks instead of each week, the number of PO Lines drops to 19 “A”s per day.

With the purchased components and raw materials properly aligned based on their relative value to your cost of goods sold, you can now define an order policy or cadence for the procurement activity. Here’s the question: How often (and therefore how many) of an item should you buy? What is the order policy at your organization? How frequently do you buy an item? When I ask these questions the most common answers I hear are: “Some of our items have vendor imposed minimum,” or “We like to keep 3 month’s supply of this item,” or “Our Purchasing approval process is based on the dollar value of the purchase order.” What about your company? At this point I go back to the comment I made earlier, Isn’t it true that you play your “A” items a little more close to the vest than your “C”s? And now it starts to jell. My starting point for a purchasing policy will be something like the plan shown in the following table. Can the organization support 65 purchase order lines per day? That is going to be a function of the complexity of the process, as well as the number of buyers and the distribution of these items across the purchasing organization. If I sense a large push back at this point, I usually half the frequency of the “A”s. If you order “A”s every two weeks instead of each week, the number of PO Lines drops to 19 “A”s per day.

Other Considerations

Purchasing volume, inventory turns, service level, inbound freight, and vendor imposed minimums are all concerns when we start discussing purchasing policy with the supply chain team. There are a seemingly endless number of ways professionals deal with these issues. What’s common with all the organizations I work with is that there generally isn’t a defined order policy based on this combination of factors. It’s intuitive – everyone knows they need to manage the “A”s more carefully than the “C”s, but it rarely exists as a formal policy.

Think about it. If we were bringing in our “A” items every two weeks, wouldn’t that imply an average inventory level of one week on 85% of our purchasing dollar (not including safety stock)? That would be huge.

Wouldn’t freight costs increase if we have more frequent receipts? Maybe. Are you capturing freight expense as a percent of inbound material? If you are not, start. You may be surprised where your freight costs really are.

Another benefit of institutionalizing this policy is the new ability to measure the impact of your vendor’s minimums. Suppose you have a “B” item where you would like to establish a cadence of monthly deliveries. The Days Supply rule would recommend that cadence, but if your vendor’s minimum order is much greater than this value you will have less frequent, larger receipts. These could be examined in the light of the new policy.

Conclusion

Defining an Planned Order Consolidation Policy for your organization is a very simple technique to drive consistency into the process. The three major reasons you want to define such a policy are:

- You will increase your inventory turns

- You will focus your supply chain team where they should be focused

- You will immediately gain the benefits of working within an established policy rather than leaving your team to their own devices when it comes to how many and when to order materials

There will always be outliers – items where a unique or extrinsic situation forces the item outside the policy. This is not a problem, it’s a fact. Aren’t these the very items that need your attention? Couple your order consolidation policy with a strong vendor portal and watch the non-value added administrative tasks plummet, giving time back to your team members – time for them to work on the important tasks they face every day.

We need to adopt new ways. We have new tools. With electronic Kanbans and supplier portals we can significantly reduce the unnecessary overhead in this one link in the overall supply chain. Planned order consolidation based on the year-to-date or requirements value just makes good sense. In addition to focusing your supply chain team on the right items (the top 85%), you are also giving them the authority to spend less time with the bottom 5.

J.D. Goodrich is a Senior Manufacturing Consultant with Decision Resources. He has more than 20 years of experience with SyteLine and CloudSuite ERP implementations. J.D. is a Lean manufacturing leader and facilitator and has held multiple positions in industry, including as the Director of Manufacturing for an electronics manufacturer.

Thank you to S&R Compression and Cross Manufacturingfor their assistance with this article

Similar Blogs

Decision Resources Featured on Crunchbase

Chips, drugs, and steel — how to prepare for Trump tariffs